Hanrun Paper now provides the ultimate in Direct-to-Film (DTF) printing with CADLINK's comprehensive software solution for Hanrun Paper DTF Printers. CADLink Digital Factory V11 features that encompass file preparation, precise color management, and efficient production automation tools. Benefit from advanced design and automation tools, meticulously crafted to save you time and effort. Elevate your printing experience with our high-fidelity color management tools, ensuring vibrant and accurate colors every time. Unleash the full potential of DTF printing with CADLINK's powerful software package.

Digital Factory Direct To Film Edition offers high-fidelity color printing and professional job preparation and management tools to streamline your production workflow from start to finish.

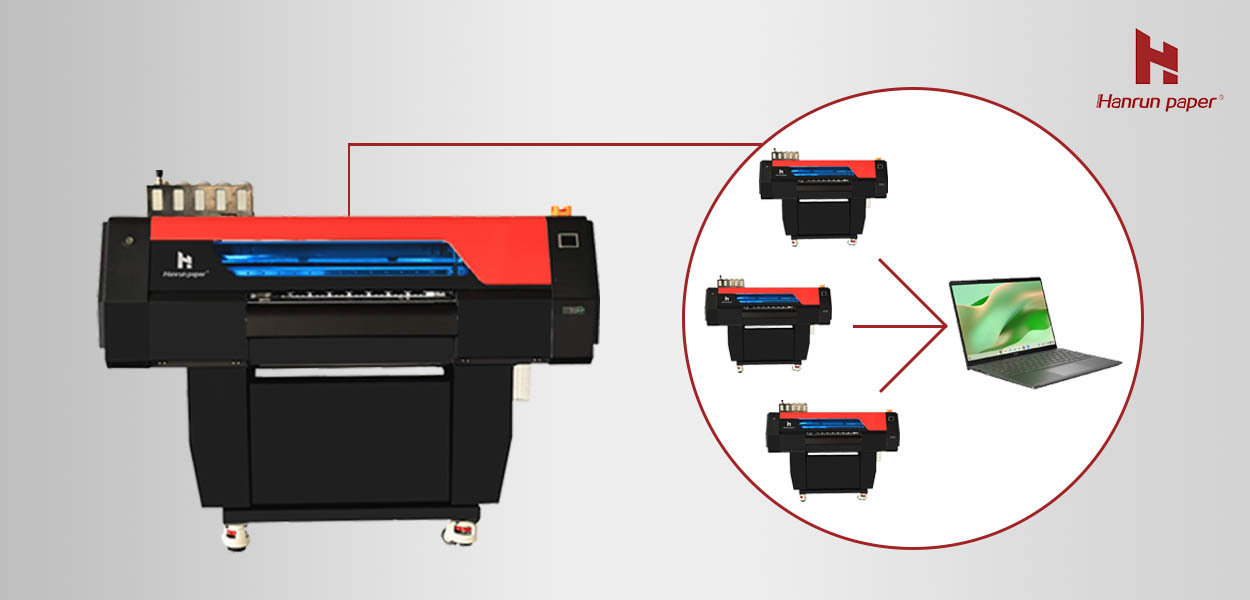

The Perfect Partner for Your DTF Printer

CADlink’s Digital Factory DTF version is the perfect partner for our high-performance dedicated printers available exclusively.

Design and Automation Tools You'll Use Daily

Dozens of valuable, time-saving features including knock-out tools for automatic black. white or color removal from designs auto nesting of jobs, barcode support, roll-mode support without the need for additional hardware or software and much more.

Robust Rasterzation Interface

Applying "ink gaps" within a design has never been easier or more visually pleasing. Transparency based application of rasters provides flexibility to place gaps over the entire image or only on select areas.

Work with Virtually and Common File Format

Industrial strength pdf support. Also supports PNG, SVG, JPG, AI, EPS, BMP, TIF.

High Fidelity Colour Management

Unique White Ink Handling

White ink is automatically managed based on transparency within the design.

Single Pass Highlight White & Underbase

Unique patent pending technology provides the ability to set different highlight and under base ink volumes to print in a single pass.

Professionally Created Color Profiles and Printmodes

Custom created color profiles supporting the most widely used ink. Media and powder suppliers.

Create A DTG Print Effect with "No Raster" Printmodes

Specialized printmodes without rasters included for select printers are able to simulate a DTG look and feel using DTF technology.

Simple Color Correction Tools

A wide assortment of color correction tools provide the ability to modify existing color profiles to handle changes in ink, media or powder suppliers as required.

All the Tools Needed to Maximize Direct-to-film Color Quality and Production Workflow

General PIR and Print Features

• Windows™ 11 and 10 support (64 bit)

• Optimized RIP processing speeds

• Optimized multiple job processing (RIP threading)

• Reduced multiple copy RIP times. RIP one copy, print many.

• Start to finish .pdf workflow support

• Enhanced plug-ins for Corel®, Illustrator® and Photoshop® that send print jobs directly to production queues with automated white underbase when required. No cumbersome job preparation required.

• Templates support for exact positioning of designs

• “KnockMeBlackOut”, black removal from design

• “KnockMeColorOut”, white and other color removals from design

• Automatic trapping (choke/spread) in queues, including trapping by color plane

• Simplified navigation; Easy queue menu tabs, page view and job properties

• Grid option in the job preview window

• Instant access to job information using “mouse-over image”

• Automated TCPIP port search for easier network printing setup

• Quick job reprints with save job backup (.jbk file) option

• Export queues and printer packages

• Worldwide language support using Unicode

• 4K Display Support

Color Management Tools

• Single pass highlight & underbase printing

• Customize ink order (Epson™ based printers only)

• Preset color profiles for white, black, and colored media of different types

• High fidelity, ICC compliant color management engine

• Simple ink volume controls

• Complete manual color curve controls by image detail (shadows, mid-tones, highlights)

• Advanced color correction tools interface

• Easy color adjustments

• Support for all widely-used color measurement devices

• High speed printmodes with no quality reduction

Pre-production Tools

• Variable data wizard automatically replaces design elements

• Visual print preview

• Raw data preview

• Multi-copy with spacing controls

• Cropping, rotation, mirroring, and invert controls of image and job

• Scale image and job to any size

• Soft proofing

• Built-in special effects/filters (distressed, distressed frames, sharpen)

• Updated Supersize filter functionality for improved image resolution

• Job color replacement

• Export template layouts with improved template user interface

• Image duplication interface

Job Management and Scheduling Tools

• Unique, single window visual interface, one central easy to manage hub for all jobs

• Easy to use queue set-up wizard. Set up production queues quickly and easily

• Automatic or manual scheduling of jobs

• Job archiving, history, print status and job logs

• Job notes

• Hot folder support

• Print label support for production directions

• Bar code support for automated production (Including QR codes)

DTF printers are known for their ease of use and dramatic results, and the addition of Digital Factory Direct To Film Edition further enhances the built-in functionality of Hanrun Paper DTF printers, providing powerful support for your garment printing business workflow. Hanrun Paper DTF printers also support Photoprint and Maintop 6.1. If you have any questions please feel free to contact us.

Choose sublimation paper? Focus on quality over price

Choose sublimation paper? Focus on quality over price

7 Factors To Consider Before Choosing A Digital Textile Printer

7 Factors To Consider Before Choosing A Digital Textile Printer

2024 Apparel Decoration Industry Trends

2024 Apparel Decoration Industry Trends

What are the features of digital textile printing equipment

What are the features of digital textile printing equipment