When purchasing a printer, the model and performance of the printhead are a focus that we all pay attention to. There is a parameter in the performance of the printheads - ink droplet size, which is an important indicator to determine the printing accuracy. However, does the smaller droplet necessarily mean that the higher the printing accuracy, the better the printing results? That is not absolutely the case. The printing effect of the finished product will also be affected by some other factors. We should consider it based on the actual application situation.

Ink drop coverage, simply put, is the coverage between ink drops on the media after the drop falls.

In the digital printing output process, there is a phenomenon called dot gain, which means that adjacent dots will overlap.

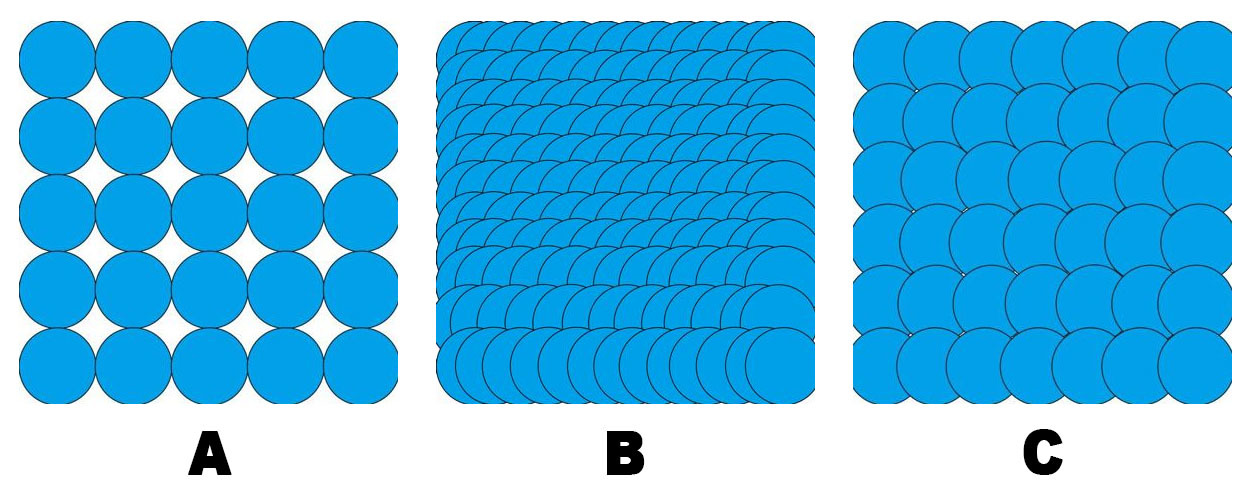

When the dot gain is too small, the print screen will have a white (Figure A); when the dot gain is too large the ink dots repeat the buildup, not only a waste of ink, and in some of the characteristics of the ink will be drawn, the appearance of the situation of the depth of the (Figure B); when the ink dot gain in a suitable value, can be complete coverage of the media, the print screen will look uniform and full (Figure C).

Of course, in some cases the need for repeated stacking of ink droplets, such as the backlight mode of printing, only the ink droplets will be repeated to ensure that the dark areas are not translucent, but most of the time, the choice of the appropriate dot gain, both ink saving, but also in the same nozzle configuration will be the equipment to maximize the productivity of the situation.

After understanding the ink droplet coverage, we must understand the relationship between the ink droplet and the medium. The surface tension between the ink and the medium is different, and the degree of capillarity (surface density) of the material surface is also different, which leads to the same volume of ink droplets in different media forming different size droplets.

When the ink droplets are printed to a smooth surface, high-density media, such as UV DTF film, the ink droplet diffusion range is smaller (Figure D); and if the print surface is rougher media, such as sublimation paper, the ink droplet diffusion range is larger (Figure E).

Understanding the relationship between ink droplets and media, we can accurately calculate the droplet coverage, rather than just take the printhead nominal droplet size directly to the calculation.

Different inks and their corresponding curing methods will also affect the droplet size. For example, UV ink will be much smaller than solvent ink after drying and curing. Because UV ink is cured instantly with the help of UV ultraviolet light, there is almost no diffusion of ink droplets (Figure F), while solvent ink is dried by water evaporation and an external drying system, the drying process is slow and there will be diffusion of ink droplets (Figure G).

After understanding the above knowledge, what should we consider when selecting equipment? Suppose, we need a UV printer to print plastic fasteners, there are three models in front of us, one has a 5pL printhead equipment, one has a 10pL printhead equipment, and one has a 20pL printhead equipment, how do we make a choice?

As written above, UV curing ink droplets have almost no diffusion phenomenon, ink droplets relative to other inks will be much smaller. Plastic fasteners are smoother, the surface density is greater, and the ink droplets after printing relative to other surface roughness of the material will also be better controlled. With the above 2 conditions, we can conclude that: the ink droplets because of the media and ink diffusion are small, and the actual size of the droplets after printing has a better control of the point size.

The next consideration is coverage. According to the size of the droplet volume of the three devices can be concluded that the 5pL printhead equipment, the droplet coverage is 10pL printhead equipment coverage of one-half of the 20pL printhead equipment coverage of one-quarter. Simply put, a 5pL printhead needs to eject one times more droplets to achieve the coverage of a 10PL printhead device, and three times more droplets to achieve the coverage of a 20PL printhead device.

To achieve the same printing results, with the same number of holes in the printhead, the 5PL printhead takes 1x more time to print than the 10PL printhead and 3x more time to print than the 20PL printhead.

Finally, we conclude that the droplet size is not the only answer to the printing accuracy, but also to consider the actual use of plastic fasteners by the user for the finished product printing accuracy requirements. Of course, the effect of the droplet size is related to too many factors, such as equipment accuracy, ink characteristics, control of the droplet spray waveform, etc., which will affect the final print results. According to general experience, 1 meter away from the distance to observe the 10pL droplet size of the screen basically can not observe the ink spot, and 5pL printhead printing can achieve photo-quality results. If it is 3 meters away from the distance observation, the 20pL effect will not feel rough. So you can choose according to the final application scenario of the product. If you choose the 5pL printing equipment, the printing effect is naturally the best, but choosing 20pL printhead counterparts is 4 times more efficient than you.

Choose sublimation paper? Focus on quality over price

Choose sublimation paper? Focus on quality over price

7 Factors To Consider Before Choosing A Digital Textile Printer

7 Factors To Consider Before Choosing A Digital Textile Printer

2024 Apparel Decoration Industry Trends

2024 Apparel Decoration Industry Trends

What are the features of digital textile printing equipment

What are the features of digital textile printing equipment